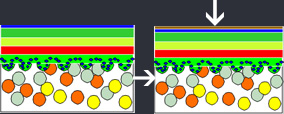

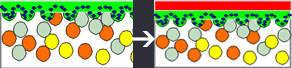

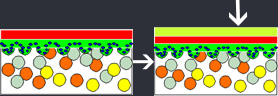

This process creates small holes on the plastic surface with Chromium sulfuric acid by taking out Butadiene to give adhesion power for plating

the process that Cr6+ reduce Cr3+ on plastic suface to protect Activation bath

Cr6+ solution

Cr3+ Solution

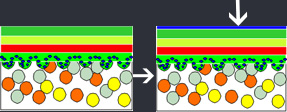

In this process Pd-Sn ion is absorbed into the etching holes on the plastic surface so that Electroless Ni can be deposited.

Remove Sn ion from Pd-Sn cluster and it can make to occur following e'less nickel process

the process make conductivity on plastic surface by the deposition of e'less nickel

Ni2+ + 2e(by Reduction agent) → Nio Pd catalyst

E'less Ni

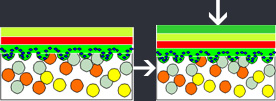

Copper plating provides brightness and the leveling effect.

This process increases corrosion resistance.

Semi Bright Nickel

This process provides brightness to the component.

Bright Nickel

This process creates pores on Bright Nickel.

MPS Nickel

This process gives white finish and wear resistance on Nickel layer.

Chrome